Backward scheduling means that production orders are scheduled precisely so they would be finished and promptly delivered by the clients’ requested delivery dates. That means everything is scheduled for the last minute, including the ordering of the materials and the production itself. This, however, cannot be manually done on a consistent basis and requires an ERP/MRP system with a backward scheduling functionality. You can use technology such as Electronic Data Interchange (EDI) to share information in real-time with suppliers to provide better coordination and communication and minimize supplier issues for the business. One of the key principles is to Eliminate waste (muda) One of the key 8 wastes is Inventory by implementing JIT you will effectively reduce inventory waste. Overall, inventory management is an excellent strategy for any business that sells physical goods.

What is your risk tolerance?

This belt-and-braces approach ensures that you can fulfill orders on time, even if there’s a sudden surge in demand or a supply chain problem. We should point out that JIT inventory and JIT manufacturing are somewhat different. Just-in-time manufacturing focuses on adding value to the production process, and only makes what customers order.

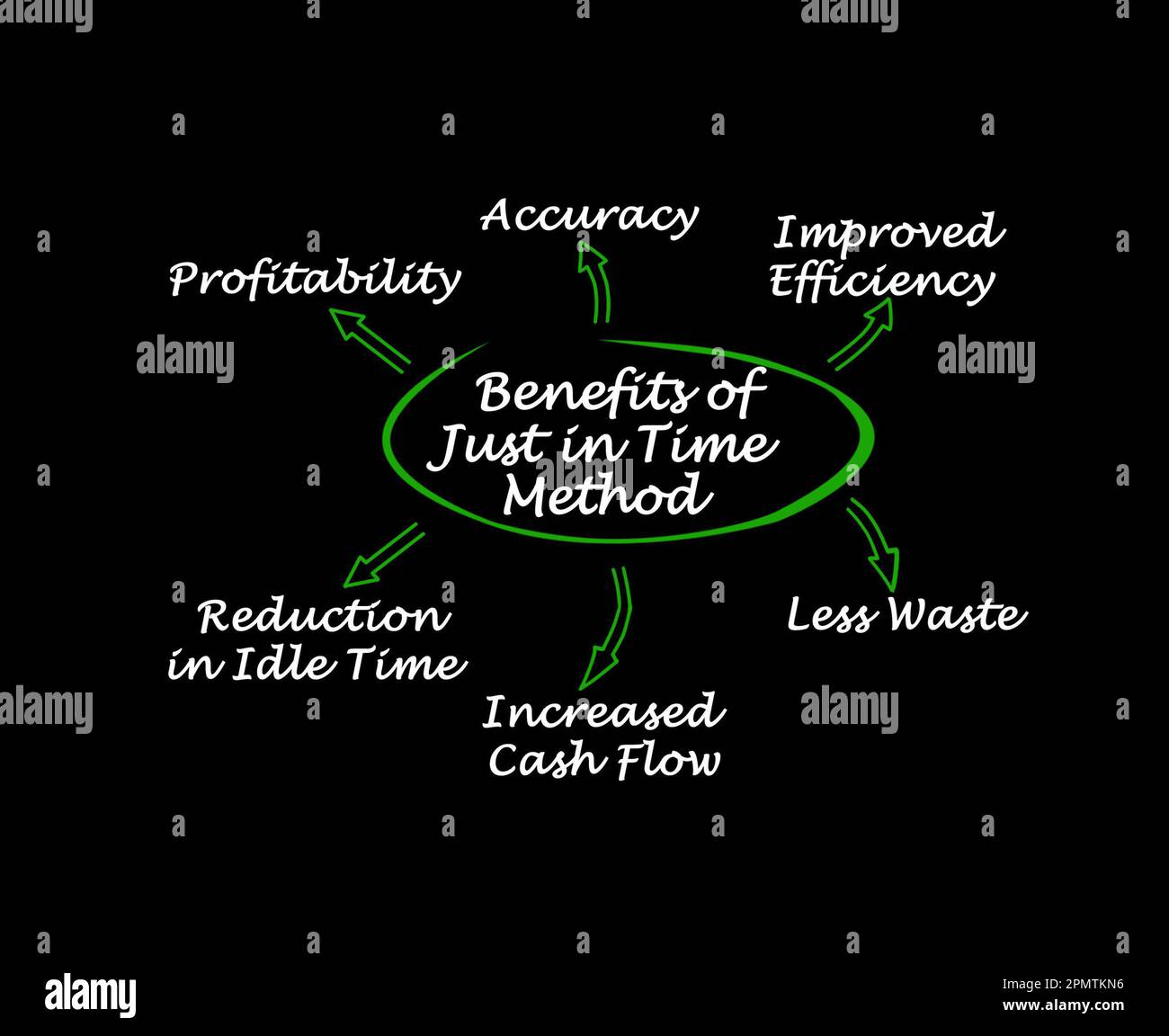

Benefits of Just-in-Time Manufacturing

If a raw-materials supplier has a breakdown and cannot deliver the goods promptly, this could conceivably stall the entire production line. A sudden unexpected order for goods may delay the delivery of finished products to end clients. For its customized laptops & personal computers, Dell only placed order of spare parts once a customer confirmed the orders. Hence there was minimum inventory storage, thereby reducing inventory costs & lead times. However, this method means you have to tread a fine line between holding exactly the right amount of inventory and not having enough to fulfill your orders.

How much inventory do companies with the JIT inventory system have?

- Let’s say you’re running a manufacturing business, and you’ve currently got so much raw material on hand that it’s taking up space on your shop floor and slowing down the production process.

- Nike then centralized all the global units with CRM & supply chain management software.

- Businesses must remain vigilant, tracking performance indicators closely, and be willing to evolve their strategies to meet production demands precisely.

- That includes how long the procedure should take and what quality items it should produce.

- You don’t have safety stock to rely on, so you need to keep a close eye on the inventory you do have to make sure it’s all where it should be and in the right condition.

We translate complex financial concepts into clear, actionable strategies through a rigorous editorial process. By addressing and minimizing these wastes, JIT aims to create lean and efficient manufacturing processes, optimize resource utilization, enhance productivity, and improve overall operational performance. Excess inventory typically means that a company has ordered more than the market demands or the demand falls dramatically after the inventory is ordered. Companies often rid themselves of excess inventory by selling it at a reduced cost or tossing it out, either of which can lower profits significantly. Also known as short-cycle manufacturing, JIT aims to produce exactly what, when, and how much was ordered – either by the next workstation sequence or the customer. The just-in-time inventory model, on the other hand, aims to order goods so that they would arrive just in time for their consumption.

Following this, you should develop a roadmap and outline the steps and timeline for implementation, including any capital investments required for changes in equipment or infrastructure. Finally, Flexibility is a key principle needed for JIT as the JIT system required a flexible workforce with multi-skilled workers who can switch from task to task as needed. Flexibility in machinery is also required to handle a variety of production tasks without significant downtime between changeovers.

See the benefits of Brightpearl’s Retail Operating System in action

Nike then centralized all the global units with CRM & supply chain management software. With continuous monitoring of all stages of production, JIT enabled Nike company to increase productivity, faster production times & decline in lead times. JIT inventory management improves production efficiency by minimising the amount of time and resources needed. ‘ As there is less raw material in stock, you may execute product modifications more rapidly. Just-in-Time (JIT) inventory management is a production strategy that has been successfully implemented in numerous businesses across various industries.

The suppliers receive the order and then supply the manufacturer with the materials needed to meet the customer’s order. The raw materials are then received by the manufacturer, assembled, and sold to the customer. The cost of inventory can go up or down based on multiple external factors, and there could be an increase right at the moment when you need to place a big order.

No matter which of these was the originator, the idea was born from Japan’s post-war lack of cash, lack of space for large factories and inventory, and their lack of natural resources. Waiting to begin one process until another one finishes is ineffective and a colossal waste of time. Some estimates claim that more than 90 percent of a product’s time in manufacturing is spent waiting. Her experience in diverse B2B and B2C industries continue to drive her interest in the SaaS customer journey. This principle involves every employee in the process of finding and solving problems aiming to incrementally improve production efficiency.

For just-in-time manufacturing to work, a customer order should reach the planning department just as the sales representative enters it into their system. The core ideas of JIT in manufacturing are that on end, the materials for production should arrive exactly when production is scheduled to begin, and not any earlier. withholding And on the other end, the manufactured products should be finished just about when they should be delivered to customers. Unnecessary transportation of materials or products within the production process is also wasteful. JIT seeks to streamline material flow and eliminate inessential transportation steps or distances.

JIT inventory management requires careful production planning to ensure that products are produced only when they are needed. This can be challenging if production processes are complex or if there are uncertainties in demand forecasting. JIT inventory management works by carefully coordinating the production and delivery of goods. Companies using JIT typically have close relationships with their suppliers, who agree to deliver goods quickly and reliably. As already noted previously in this article, JIT is a great cost-reducing technique. It’s also difficult to react to sudden market demand when you have a limited inventory of materials.